Plastic ductwork is used for the safe transmission of chemical, biological or radiological fume. BESA sets the UK standard for fabrication and installation of plastic ductwork via DW154. Only BESA specialist plastic members are audited by BESCA for quality and compliance with DW154.

Imagine ductwork which runs above the suspended ceiling of an office

Imagine that it runs to a discharge stack from a laboratory fume cupboard doing HIV or COVID 19 research, or perhaps using Hydrofluoric Acid.

If you were sat in that office, would you want to know that a specialist did the job?

Lower quality fabrication, or a poor standard of installation, doesn’t mean an inconvenience, it means a potential catastrophe.

The most common DW154 non-conformities made by non-specialist contractors:

- Using the wrong material: PVC is cheaper than PPs, and easier to install (it can be solvent welded, whereas PP cannot). Whilst PVC may be suitable for a number of fume extract projects, it doesn’t have high resistance to solvents. PVC is a dark grey, PPs is a lighter grey, but to the unsuspecting client, plastic is plastic.

- Using the wrong jointing method: hot air welding is a skill, and requires investment in specialist equipment. Screws require a screwdriver.

- Using a sealant: mechanical flanges with a suitable gasket, hot air welding, or solvent welding (PVC only) are the only acceptable methods of sealing ducts – silicone, bitumen, tape are not (but they’re cheap, and does the unsuspecting client know they’re not permitted?)

- Trying to join incompatible materials: PVC cannot be welded to PP (and vice versa), no matter how many times you try!

- Using thinner material: DW154 specifies the thickness of material required depending on the dimensions of the ductwork. 3mm material is 1/3 cheaper than 4.5mm material, and once it’s in the air, would the unsuspecting client know?

The solution? Use a specialist plastic ductwork BESA member. Specialist BESA members are audited by BESCA, for quality of fabrication and installation. If you don’t use a BESA member, you don’t have that assurance. Simple.

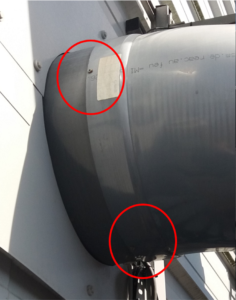

Inlet ductwork screwed together. When the screws corrode, condensate will drip out through the hole at the bottom.

Steel fixings will corrode, and you will be left with holes. This is the discharge side of the fan, so fume will be under positive pressure and will leak out.